Work on the plane stopped for a few days while I worked on the car and a few other projects. I plan to start back on the bird tomorrow…

After installing my WVO fuel tank the next step with the car was fixing a few nagging ventilation issues and designing/installating of my greasecar computer.

The center vent for some reason stopped working which made cooling the car much more difficult, besides, I love having the wind in my face when I am driving or flying. After a bit of investigation I found the vacuum diaphragm was ruptured on this vent controller. Need to get it out and fix the dashpot.

Such a simple looking thing…

Yet I had to go to hell and back to get it out……

Now I know why they charge so much for Mercedes work. I had to disassemble half my dash to get to the thing…. Of coarse it is in the worst place imaginable. I guess that is why it failed…becuase I haven’t been spending much time with Sherman.

After spending a few hours with my books on the AC system I also tried to reprogram my vent operation controller to do what I WANTED it to do.

I basically gave up trying to re-educate Sherman. Sometime there is no changing the way old people (or cars) work or think. You just have to accept them for the way they are. He get the AC job done, in his own stately time in a crazy mix of opening and closing vents which I will never understand. Fixing the vacuum dashpot seemed help a lot in cooling the car down on a hot summer day, so I am good for now. I also took the opportunity of some free time to wire up the sensors from the engine into the cabin for hook up of my custom designed grease car computer.

The human brain is a wonderful thing. What I could do so easily (watch the temp, turn on a switch, shut the system down) is really tough to design into a circuit….I would like to say my design worked like a champ, but I cant.

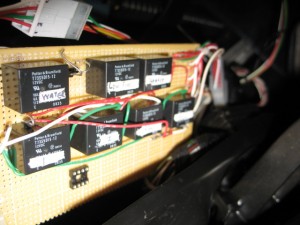

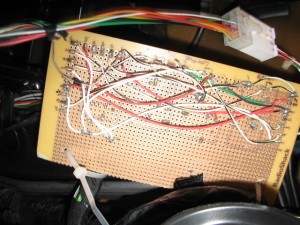

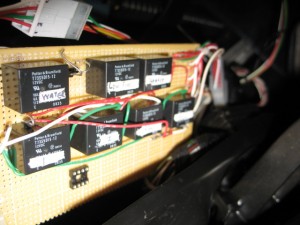

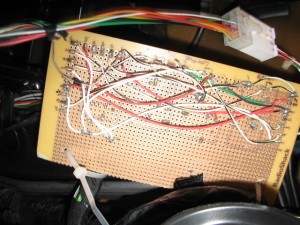

This is it…

After frying some diodes and LED, I disabled a some of the features I worked so hard to build, and returned to basically what I originally had. Shit….. It should work as I planned it. Although I spent a lot of time the last few days messing with this stuff, I can say it was a good thing because I’ll have to assemble some boards for the plane. This project gave me some valuable experience in this direction.

I plan next to take most of what was built apart, and then just enable small module of the “brain” to see if they work or fail and then trouble shoot the new circuit. Assembling the whole thing, hoping it would work and then trying to trouble shoot is proved to be too much…..

Maybe I should just stick to plane building…..

UPDATE:

I have fixes the wiring (actually it was very simple) and updated the wiring schematic on the computer. It has been working great for months!!

GreaseCar control system drawing (pdf file)

Enjoy!