May

31

2011

Today was spent working on the new eductor tubes.

First step is to get an idea of what the eductor is going to look like. Some foam was used at templates to outline the inlet and outlet shapes as well as the overall length.

The shapes were wrapped with some heavy paper to use as a template to make the aluminum tubes.

The inlet of the tube is flared to smooth the air going into the eductor.

All that is needed is to mount the nut plates on the tube and I’ll be ready to test! Tomorrow morning I’ll check out the results.

May

30

2011

I have been having MAJOR issues with engine cooling. I can get up to a max of 2400 rpm before the CHT’s get up to 425f. Yesterday I decided to go flying before I cut off the front of the inlets and installed larger cowl inlets to let more air in the cylinder plentum boxes. Sure glad I did as I found out it wasnt the inlet size, but major cooling issue is back pressure in the cowl area. I thought I would just cut some reverse scoops in the cowl per Jerry Schneider’s SOOMA analysis (Jerry’s famous “Straight Out Of My Ass” method of problem solving).

When I woke up this morning, I realized the only difference between my plane’s cowl (excellent cooling) and the new plane’s cowl is just eductors. I do not have holes cut in the cowls to let the air out so openings might not be necessary in the new plane, just a set of eductors.. cool!

When I went out to the club today and took a close look at the cowls and sure enough, I notice a LOT of carbon on the cowl just aft of the exhaust pipes. AaaaHAAAA… the hot exhaust is basically clogging the outlet of the cowl not letting the cylinder cooling air out

You can see on the cowl how the exhaust was backing up in the cowl and most likely causing a pressure wave not letting the cooling air out.

I have two choices, extend the exhaust pipes or build eductors like in my plane, so I fabricated a set quick and dirty set of eductors for testing.

These are the pictures of the cowl and my temporary eductors made out of house flashing, and went flying.

Overall the minimal effort was a very good success as my temps were much better (almost normal) until one of the eductors ripped itself from the plane at 203 kts TAS and was apparently eaten by the prop at which time the temp of #3 (my hottest) cylinder again quickly started climbing up.

I think I am now on the right track and will be building a formal set of eductors tomorrow.

May

19

2011

I am playing catch up on the blog once again. The plane is flying now and I am fighting high oil and cylinder temps….

Speed is great. 160 kts at 2380 rpm. So far she has been up to 186 kts IAS flat out for a short time. Still trying to figure out how to interpret all the information I am getting from the GTR EFIS. Now that the plane is at the airport, my evening are a bit more free and I’ll try to get you up to date…..

UPDATE: Today I went flying and at 2500 ft 2900 rpm top speed of 208 kts (240 mph) TAS was obtained. I easily went up to 220 kts (253 mph) TAS on decent. Wow!

May

11

2011

Today I found a number of delimitation on the canard which need to be repaired.

Delam can happen anytime, but I have seen it more often on new wings/canards. Not a big deal and is very easily fixed.

The following the best and overall quickest way I have found to take care of blisters (delams from the foam). This procedure is ESPECIALLY useful for painted or highly curved surfaces because of the absolute minimal damage to the surface.

- Take a chunk of foam scrap (I like wing foam), place a piece of sandpaper near the area (sandpaper side up) and sand the foam to make a contoured foam block which matches the contour of the blister area. This is critical for highly curved surfaces such as the canard.

- Put clear packing tape over the area as large as necessary to protect against accidental epoxy drips.

- Identify the exact extents of the delam usually by pressing around the edge (or just looking (optically). I usually mark it with a felt tip on top of the clear tape.

- Drill small holes for epoxy through the clear tape. One at either end for small delams (2 holes) or for large ones, one center and a number around the edge depending on the shape.

- Cover the clear tape with aluminum tape just over the delam area.

- Locate and reopen the small holes you have just drilled.

- Inject pure epoxy in the center hole for large delams or one end for small delams.

- Make sure the epoxy flows out the vent holes by pressing and squeezing the blister. Squeeze out as much as possible from the vent holes. Excess epoxy will result in a bump on the surface when cured.

- Put a piece of peel ply then some paper towel on top of the alum tape

- Put some clear plastic on the paper towel

- Place your contoured foam block on top of the plastic and weight it down (the more the better) or if you have room clamp it down.

- Let cure

- Remove weight (clamp)/foam/plastic and yank off the paper towel and peel ply

- The peel ply allows you to really get vertically all the epoxy off.

- Using sand paper carefully sand the small epoxy “pipes” that are formed at the hole site. Note:The alum tape is hard to sand though so it is easy to aggressively sand off the excess epoxy at each hole without damage to the surface.

- Take off the alum tape

- Remove the clear tape

Now you will be left with a perfectly matched contoured surface with NO epoxy on the paint, and you’ll only have just a few small clear little tubes of epoxy remaining. If you want you can sand the tubes off with 1200 grit and polish, but using this techique results in almost nothing at all except a tiny clear bump on the surface and I don’t worry about it..

I know this sounds a bit long, but is is just technique and the steps go very quickly. Most importantly, the surface is totally protected and you’ll end up with a properly contoured surface with almost no damage to the surface. It saves time in the long run.

I hope this helps.

May

02

2011

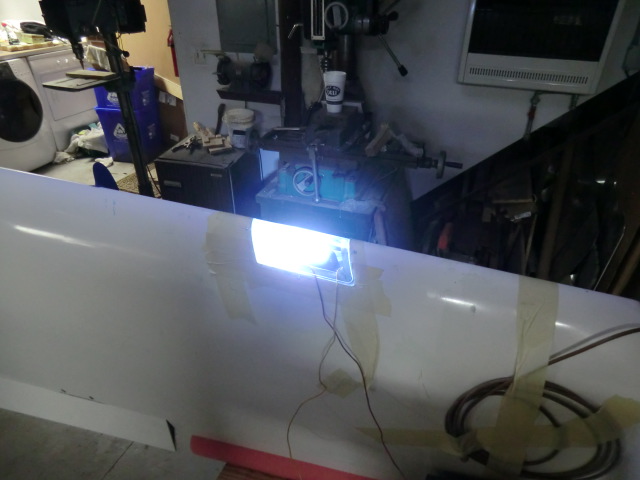

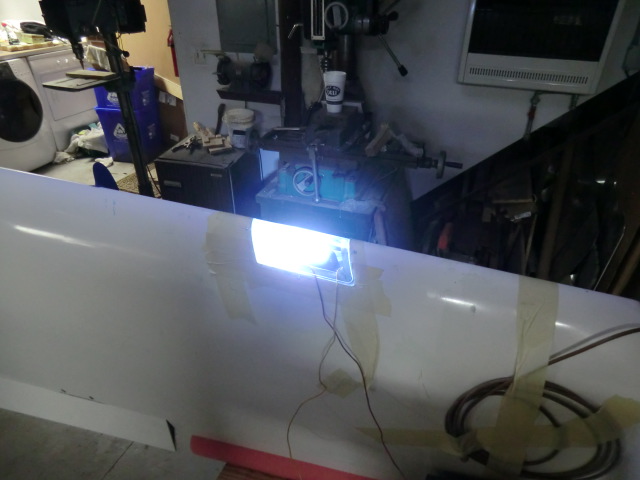

Today I am molding the lens for the wing lights. After a number of tests I found I could bang them out quite easily.

A couple of notes….

1. Cover the splash with some fabric. I found an old tee shirt taped to the splash to prevent wrinkles (which will show up in the lens) after cooling

2. Heat the oven to about 250F

3. heat the Plexiglas for about 15 minutes

4. when you removed the Plexiglas from the oven work quickly (as it cools VERY quickly) . Keep it covered with a warm towel to prevent cooling

Here is a bunch of them made as spares.

I tried heating the oven up to 350 f and the plexiglass started to bubble.

Now that the lens are made I outlined the shape I wanted for the opening and started cutting.

and cut out a cavity in the wing. You can see the flange on top of the wing will will slid into the opening and floxed in place.

This is how the the lights will look installed. You can see the lens mounting flange loosely planced in the light opening.

Very cool!

I need to make a webpage on this subject….. I have lots more details on each step… so many projects and sol little time.. Here is a few more picture for you.

After installation, I wanted to be sure the structure would not be impacted by heat generated by the light. The light was powered up and I left it on for about an hour to see if the surface of the wing was hot. The surface was barely warm in static air, so when using the lights in flight the wind will provide a lot of cooling. So I determined the operation of the lights resulted in no impact to the structure.

Update: I found the lenses would crack at the screw holes. I went though a couple of set of lenses, trying different way of attaching them with no joy. The last time I had my car windshield replaced I noticed they used an adhesive so I finally decided to just use adhesive to glue them in place (used clear RTV). Worked great.