After waiting for months looking and checking out phones, I finally decided upgrade to a data phone. Yes, I am going over to the dark side of unlimited data, texting (whats that), talk, everything.

I remember my first cell phone and how reluctant I was to get one. I didnt want to be “tethered” to everyone via a wireless connection. Just thenk about it, I’ll be a the beck and call of everyone and expected to be there all the time. Years later here I am, enjoying the on line community and rapid pace of instant contact.

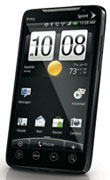

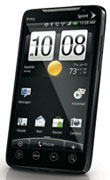

I decided on the Sprint EVO. It is at this point the most advanced and highly rated phones on any market (including the iPhone).

This phone has it all from HDMI out (which I can hook up and stream movies directly to a HD TV) to recording HD movies, video conferencing, 8 megapixel camera, creating a wifi hot spots for up to 8 computer, sending movies, pictures, EVERYTHING you can possibly do on a phone/computer. It is also a 4G phone which means it’s data through put is as fast as a cable modem (if you are in a 4G market which will take about 2 years to get here in Charleston). They are VERY hard to get right now as they are extremely popular and out of stock just about everywhere.

After changing my data plan from $59 to $79/month which takes affect on my next billing cycle (26 Sep) I was contacted by Sprint Customer support on my experince with the representative. Here is my response:

— On Thu, 9/9/10, CustomerSatisfactionTeam@sprint.com wrote:

Thank you for contacting Sprint today and for giving me an opportunity to resolve your issue. I have made a personal commitment to provide my customers world class service. My goal is to make certain you can say YES when asked if your issue was addressed and resolved. Improving our customers’ experience and resolving issues on the first call are our top priorities.

If you require additional assistance, or, you believe your issue was not resolved, please reply to this e-mail. Your response will route directly to my manager……..

—-My response on 9/11/10

To answer your automate survey question, YES and NO.

YES your customer service rep did an outstanding job of changing my plan while retaining my bonus minutes which made me very happy.

NO Sprint has some screwed up business policies which does its’ best to make me wonder if I am making the right choice by continuing my association with Sprint.

After making my decision to upgrade my plane I quickly went to the local Sprint store to buy my EVO. They had one in stock now! I was told if I purchased immediately it I would have to pay a $40 pro-rated amount to switch plans (to execute my more expensive data plan) immediately instead of 2 weeks from now on the Sept 26.

I also so found I could NOT purchase the phone now for future (since it is in stock) with out the plan. If I waited 2 weeks, it might NOT be in stock and would have a plan without a phone.

This is very upsetting to me as a customer, and a senseless business practice. I decided to wait two weeks. So here is the bottom line.

1. Sprint policies once again upset me off as a customer.

2. The EVO phone may not be in stock when my plan changes.

3. I will keep my old plan (saves me $40), so Sprint does not lock me in under a new contract for 2 more weeks (I will be looking for something else in the mean time).

4. Sprint does not get the benefit of me paying for a higher $20 data two weeks soon than scheduled which means Sprint loses $20 in profit.

5. Allowing me to change plans immediately does not cost Sprint anything.

6 . Sprint once has proven why Consumer Reports ranks Sprint at or near the bottom in customer satisfaction and why Sprint has had a mass exodus of customer to competing services.

Now all said, I am happy with the cell phone service I have had with Sprint for the past 10+ years. It is little things like this stupid policy where I, as a customer, WANTS to upgrade to a more expensive plan, NOW, and being told I have to pay more to do so which makes my dealing with Sprint customer service painful and to be avoided….

In my opinion Sprint has one thing going for it…..price. Sprint’s customer polices haven’t changed over the years which is sad after seeing how hard Sprint is fighting to retain a solid customer base.

It will be interesting to see if I hear anything back from Sprint. Either way, the last EVO at the Sprint store has been sold. Hopefully they will be more stock in the next few weeks.