An instrument panel is born

I decided to take a few pictures of the current work as I am going to take a couple of days away from the work to get a some chores done. Sort of a working vacation.

Here is the shape of the outlet duct I came up with. It is a much smaller outlet than original and compresses the air prior to injection in the airstream. I wanted a slight kick out to create a low pressure area just in front of the outlet (somewhat like my plane which I know works well. When I start flying the bird, I’ll record some data reading to see just how well it compares to my plane.

the oil cooler was tilted 25 deg from orginal. Te final effort is creating the inlet duct. Some sanding and it is ready for paint!

I made the decision to organized all my electrical stuff. It is much more efficient to have everything inventoried, organized and easily assessible to speed up electrical work. I was getting frustrated looking for stuff asit was slowing my progress down.

A table full of … stuff…. Now I have to sort through all this stuff and get it organized. This will take HOURS (but time well spent ).

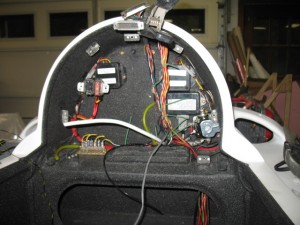

I also wanted to populate the instrument panel to see how it would look and it is freaking beautiful. This picture doesn’t even begin to do it justice. It it going to look fabulous when installed in the plane!

I am extremely pleased with the result.