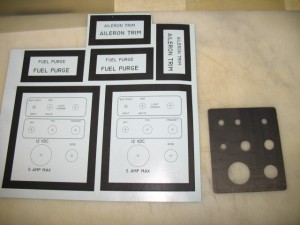

The lettering is completed for the panels prior to clear coating in Calif. They will be sent out tomorrow.

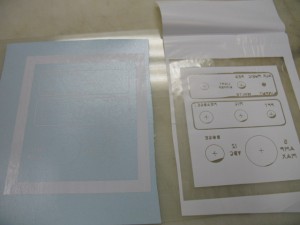

I thought I would give you an idea of the steps involved using the Pulsar system. First you must print out the graphics on their special paper

Then you chose a color you want and bond it to the graphic, white in this case.

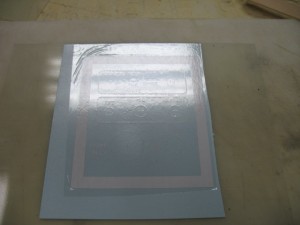

After bonding you peel it off the color film, (you can see how the image was transferred from the film on the right)

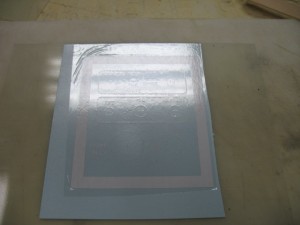

Then you take a clear film and put it on the image. It is SUPPOSED to cling by static electricity to the image.

Then you put it into water, which is SUPPOSED to let the water get absorbed from the backside of the paper. Then the water is SUPPOSED to travel to the front side, releasing the graphic (which clings to the static film), then you pull it out of the water and glue it to the panel.

This is one convoluted process, but IF IT WORKED reliably as advertised, it would be great. You could make all sorts of graphics for quick transfer. Too bad it is so hard to use. It took me 9 tries ( each try took 15-20 minutes) before I finally got a good transfer on the right panel.

I have started investigating silk screen printing. There are all kinds of ways to accomplish it from sheets of pre-applied photo resist screens, to “do it yourself” methods of applying the chemicals to the screen. The nice thing about silk screen paint is that it VERY TOUGH. You go through the same process as what I have done with designing the computer graphics but making the screen takes time. Overall, with all the wasted time spent with Pulsar system, I have easily made silk screens. I called a local art store today and talked to them about supplies and they have everything I need. I am going to check them out and get some supplies to play with.

Now to the plane, I started on canopy latching system and again found more little problems to solve. To me building a plane (and more so with RE-building a plane) is just a series of continual little problems to solve. The canopy latch system I bought from Jack was the wrong size so I had to reuse the original latch system. The threaded rod in one of the of the parts was destroyed by the anodizing process. The lath was necessary to remove the stub. The rod was quickly repaired.

Then I found out the anodized handle (right) would not work (geometry wrong), so a new one needs to be made.

At least I am doing fun things now… solving more problems and building parts!