Today, I reached a few personal milestones by shipping off the instrument panel and installing two capacitance fuel probes of my design. There is a a bit more to this story so get ready for a long read.

First,

I completed everything left to do on the instrument panel, wrote the testing and modification procedure for Pat, then shipped it to LA by FedEx 3 day. P1 Prototypes (Pats composite fabrication company) has some shop time available (by his top technician) and he will personally build and attach radio brackets, leg opening flanges and clear coat the panel to my specifications. It will come back ready to install. How cool is that?

Second,

For years, while visiting airshows, I always checked out vendors looking and comparing various remote capacitance fuel probes (because I wanted some in my bird). They were all very simple, small and reliable, and VERY EXPENSIVE ($150- 175 each) and I am too dam cheap to spend mucho dinero for a simple product which doesnt even include the electronics. Ouch! A few months ago I had an idea to make a probe setup specifically designed for a canard installation. Finally, a fuel probe which would work in a non-Cozy canard.

Non-Cozy canards are built in way which does not lend itself to the installation of capacitance fuel probes (CFP) . Cozy’s have a nice fairing forward of firewall which can be used to cover and hide the probe installation. I have seen a few attempts to install probes in LongEZ’s, but have never liked the final look of the avaliable products. Either they are puck type which is harder to seal, or they are WAY too tall to hide. The only advantage to these systems is that they are removable after installation. Mine are not, but what can go wrong with a tube and with a wire in it?

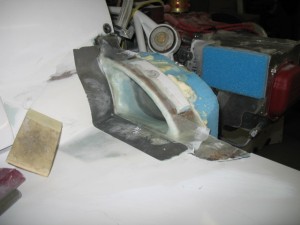

Initially the design started with a probe. A proper installation requires a very short probe less than 3/8″ tall. The shortest probe I have seen was at least 1.5″ tall (or a puck at 1″ tall). This probe’s height is sized to fit into the space of the 10mm foam core of the strake. After many designs a working prototype was finished.

Less than 3/8″ tall it can be easily and quickly installed. Is is completely invisible after installation and fits nicely in the foam core space.

A test cell was built to check the height dimension, the dielectric constant of two epoxies and the accuracy of the voltage output for two common fuels I use, MOGAS and AVGAS.

Next, some electronics are needed to make these probes work.

I knew Princeton Technology built capacitance electronic fuel probe modules. They build puck styles and other various remote probe styles and has a great reputation. At the SNF airshow last year, I talked to Todd Stehouwer (the owner of Princeton) and finally convinced him to let me help him. I could easily see a wide open market for an EZ probe system. As many canards owners rewire their canards to install improved electronic systems such as Grand Rapid, Dyson, ECI, the market was wide open for a new product line. All that was needed is Todd’s help to develop an EZ specific electronics product so he could sell product to make mucho dinero Why did I do this? Because I freaken needed some for myself and someday I might need his help. “Pay it forward”!

After many months of emails, calls, a few miss steps, Todd finally completed the engineering for the module needed allow this probe to function. He used the test cell I sent him (MGS with AVGAS) for setup, calibration and testing. The nice thing about his electronics module is that it has FIVE calibrations point to fine tune the electronics to your fuel tank profile and can be used with either AVGAS or MOGAS (you have to recalibrate it for the dielectric of the fuel).

Well, call me an over cautious engineer, but I always have to check everything out before I put my cra*k, oops, foot out there to get stepped on. I want to be sure I would be as happy with this design as if someone else presented me with a similar design for evaluation.

Here is a couple of issues of concern to me.

1. Will fuel resistance of either WEST or MGS (two common epoxies) work for this application? I know MGS is multi-fuel safe. A quick call to WEST Tech Support confirmed WEST resin is fuel safe for AVGAS or MOGAS (NO Ethanol) fuels. My main concern was the possiblity builders might no have MGS available, but most of us have WEST handy (or can easily go to a local boating store to buy a pint). Epoxy/fuel check …good.

2. Next does the epoxy affect the overall capacitance of the system? Epoxy is a dielectric. Is the dielectric (hence functionality) a factor and/or epoxy dependent? I built two test cell to evaluate. One using WEST and one using MGS epoxy.

After testing by Jack Wilhelmson and myself, we found the epoxy made no difference to a calibrated probe in AVGAS or MOGAS. Epoxy/Capacitance check …good.

3. Does the OVERALL system work reliably? A test rig was set up and after gathering about 40 data points, I found overall the system works very well. Voltage output for different heights were exactly repeatable about 85% of the time. Sometime, it would just be off just a small amount 0.1-0.2 V or so, but no surprises. I dont even know if that small a voltage would make a difference on a display. This could be partly due to the difficulty of measuring the capacitance on a 7.75″ probe (the height of the strake) or the accuracy of the VOM. Todd and Jack also tested the electronics. Accuracy check. …good.

Here you see the probe sitting in MOGAS at “FULL” tank level in my home test rig. The voltage shows is 4.96v.

To calibrate the system, just fill your tank to your personal “empty” level …press “SET” to lock in “Empty” point. Fill the tank to the 1/4 level (or fuel gals)… press “SET”. Repeat for 1/2, 3/4 and FULL. Took just a few moments.

Before you read further be warned, in my opinion everything in life has Ying, Yang….. the Black and White, Good and Bad sides. Here is this probe’s good/bad side.

The BAD:

1. This is a PERMANENT install. Everything is glassed into place. You’ll never get it out. Be smart and careful with the installation.

2. If it stops working, you’ll have to abandon the exiting probe and install one in a new location.

The GOOD:

1. It is the only probe/electronic system specifically designed and built for a canard aircraft (Varieze’s to Cozy 4)

2. The electronics are easily removable/serviceable (there is a quick disconnect on the fuel probe wire).

3. It is VERY easy to install in a few hours. Installing two probes took me around 2 hrs and I didnt know what the heck I was doing!

The UNKNOWN:

I have done my best to ensure this solution will work. I wanted to test everything and be as absolutely confident as possible before I spent the time installing it. Before I recommend it with complete confidence, I still need to complete the wiring of the plane, calibrate the system with 100LL and gather many data points comparing the sight glasses and electronic output over an extended period of time .

If you are a experimenter like me who likes to try new things (testing indicates this system will work) then go for your own installation. If you are a timid soul, then I would recommend waiting until I start flying this bird and get some real life data before thinking of installing it.

The Installation:

Now the fun part. The entire process took about 2 hrs start to finish.

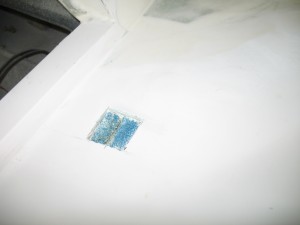

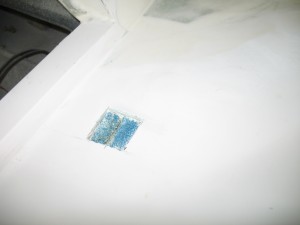

Measure and cut a hole in the outer skin of the plane.

Remove the foam to the inner skin. Sand the inner skin.

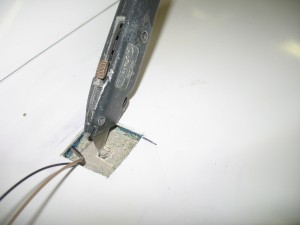

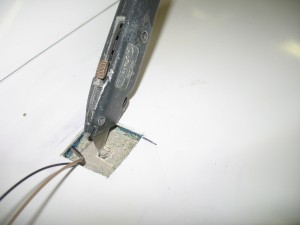

Drill a 3/16″ hole horizontal below the Longerons, into the foam below the upper skin. Fish the wires though the hole.

NOTE:

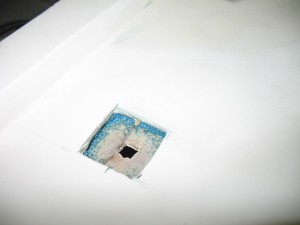

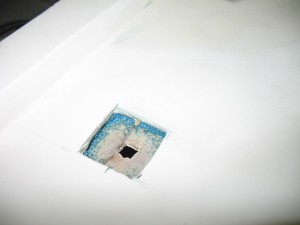

When I drilled the holes for the wires, I drilled from the cabin to the strake and was afraid I would drill into the tank. Being careful, I angled the drill a bit too much and punched a small hole in the upper skin. No big deal. Better than drilling into the tank. A little filler will make for an easily fix.

Were I to do this again, I would drill from the hole into the cabin. Just take some welding wire, flatten and sharpen the end into a flexible drill. Insert your home made drill into the foam from the hole side and you can easily bore through the exterior and interior glass sides. Using the pilot hole you can then follow it with a real drill from the cabin side….. NO CHANCE of drilling into the fuel tank!!

Lastly, use the razor knife to cut a square opening in the glass inner skin of the strake for the probe tube. The razor knife is used to prevent the possibility of getting some chips into the tank which wound invariably happen if I had drilled a hole. After you cut the 3 sides of the hole, just bend the tab up and break it off…. no chips.

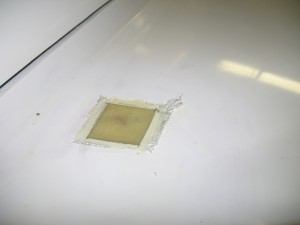

A nice hole, all sanded and ready for glassing. Attach the wires to the probe.

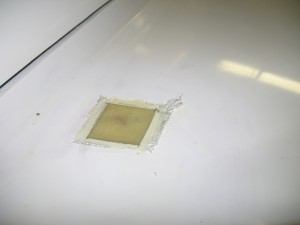

Mix some wet flox, and butter the bottom of the probe, install it into the tank and then fill the entire cavity with even wetter flox. The probe/wires are completely encapsulated (potted) into the tank with wet flox…. did I say it is permanent? In my mind there is no possible chance of fuel leakage.

After a bit of reflection, I could see a few variation to an installation….

IF you DID NOT wish to immediately repaint, just cover the area around the hole (to protect your paint), cut the hole and install as shown. When cured, remove the protective tape/paper for an unblemished paint job. Make a painted Alum cover (like wing bolt covers) and RTV it over the probe hole. Save the painting till later.

IF you wish to immediately repaint the area, first mark the opening, take a sander and feather the micro back 1/2″, THEN cut the hole. When floxing the probe incorporate 1 layer of BID in to the repair. After curing cover the area with micro and sand every thing flush. I doubt you would even have to put a second coat of micro on it. Then paint.

If you are interested in purchasing the electronics call Grand Rapids Technology and ask for the Princeton CANARD capacitance electronics box. Princeton is selling the CANARD module (with 5 calibration points) for $95 each .

I am considering selling the probes for $40 each if anyone is interested. You can easily make your own… I did it. I thought about detailing the construction of the probe, but decided against. I know it is a few $$$, but I’ll be more confident they will work correctly for others if they are an exact copy of mine which has been tested. By the time you buy the materials, have them shipped to you, machine the parts in a lathe, etc, it is not worth your time and expense. I certainly wouldnt have gone though all this shit if I could have just bought a system off the shelf for a few bucks.

One afternoon while Todd and I were talking and trying to find a suitable name to order this specific electronics modification, Todd suggested calling them the “Nick Ugolini” electronics. It is the name Todd jokingly gave them due to the frequently calls I made to get it working. I thought it might be a bit to pretentious so I thought it best to decline….

Am I humble sort of guy or what?

What?