Make your own MIL SPEC teflon wire strippers

I love to wire airplane. To properly wire, you must have the CORRECT tools for wiring.

One of the MOST important tools I have is my wire strippers. Why, because the wire we use in airplanes is VERY small, generally #20 or #22 wire and if you use the wrong stripper you can tear off the fragile wires of the core and reduce the current handling capacity of the wire.

YOU SHOULD NEVER USE ANYTHING OTHER THAN A MIL SPEC WIRE STRIPPER. NEVER

Two years ago, I bought a really Snap On teflon wire stripper at an airshow which cost me a whopping $200. The reason I paid so much is for this one reason…

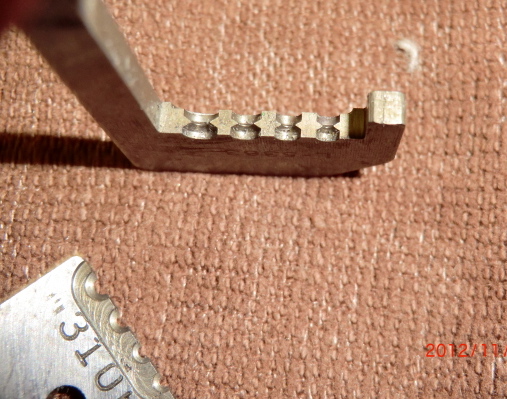

These little puppies. The blades. The one on the left is the standard blade you’ll find in tool boxes. The one on the right is a MIL spec blade found in the MIL SPEC stripper you should be using on aviation wire. The main difference is HOW it strips the wire. Almost everyone I have talked to don’t know the difference between a regular wire strip and the Mil Spec stripper.

If you look closely at the blade of the “non-approved” stripper it has VERY sharp teeth which cuts the insolation and many times the wires themselves. There is only 16 threads of wire in the small gauge wire, and if you lose 2 or 4 of them, you reduce the current capacity of the wire and weaken the termination point.

The MIL SPEC blades basically grip the insolation and tear it off. The wire openings have nothing shape on them to cut into the wire at all so you never cut the individual wires, you end up burnishing the wire bundle.

This is a better view of the inside of the blades.

I happened to have an old stripper (with the sharp cutting blades) laying around I picked up somewhere for $7.50. I remembered that I had and some replacement blades sitting around for 10 years which I bought at the Sun-N-Fun

“Fly-Mart” for about $15 but had never opened the package. I didn’t realize they were actually worth about $84 when I looked them up on line. So I thought why not use them.

To make your own professional stripper, just order the blades of your choice, and replace the sharp ones

with the MIL SPEC blades and save yourself over $100. It took me less than 5 minutes.

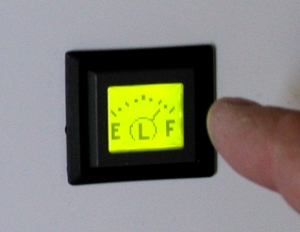

The stripper on the the left is my $200 Snap-On, the one on the right is the $22.50 stripper with the same blades that I put together from parts I had on hand.

If you want to save some $$$ just find an old Ideal wire stripper (for the frame) and order the PROPER Mil Spec blades on line.

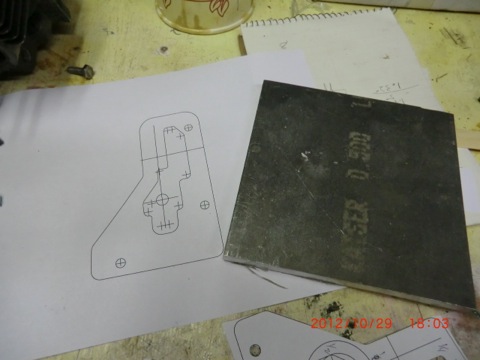

You can see the different type blades for the Ideal Wire Stripper here.

The L-5363 blade I installed which is good for for #16-26 Teflon wire can be ordered for $84 from Stanley

This blade should will take care of most if not all your wiring needs on the plane. Enjoy.