Cooling Intets

On Sunday, I had a great day after church cutting up a downed tree and hand splitting the wood. Actually it was a lot of fun using an ax instead of a log splitter. A bit of work but great exercise.

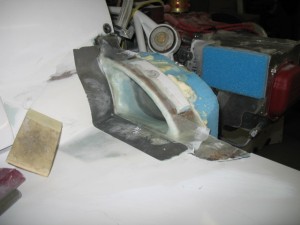

I have shifted directions on the down draft cooling system. After carefully looking at the cowl, Pat and I decided that the reduction of the height above the cylinder (due to the DD cooling plenums) did not warrant chopping up a beautiful cowl. If I had not cowl it would be a different story. Overall, I would save a considerable amount of time by keep the cowls a close to original as possible. The first step is to reattach part of the original fairing.

Foam was bonded to the inlets, shaped for glassing.

There is an Alum ring (which you will see later which will be used as a support for a silicon vibration isolation tube. The inlets both have about 12 sq in per side. It should be plenty for cooling as it is about the same as my plane and my cooling works exceedingly well.

Tomorrow, I will reshape this area, and start working on the inlet tube to the engine. I feel shaping of the inlets is the hardest part of the down draft cooling. The rest of the work is very simple.