Makeing a Wobble Tester

This is a potential damage which could occur if you lose an exhaust valve. This is what is left of the head which was on my plane which caused me to do an emergency landing at Summerville Airport. I ended up with a cracked crank and had to do a complete engine overhaul.

The valve head broke off due to excessive clearance of the valve guide to the valve stem.

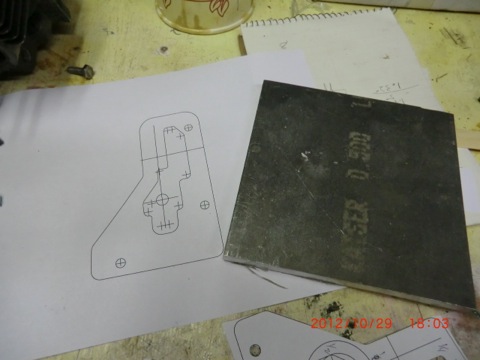

I decided to build the wobble tester, and check my valve clearances before I put the overhauled hydraulic lifters in. It took me a few hours I get a design I was happy with in AutoCAD. Actually making the tester only took me about two hours to build. The design is a bit different than the factory model as I mounted the dial indicator from the top down, between the rocker rod support columns (on the top part) which is opposite to the normal mounting (from the bottom up) which would require me to take off the exhaust system to test the wobble.

It allows me complete the test and not removed the exhaust system to do the testing.

The final result is made out of 1/2” aluminum plate.

Here it is being used on an old cylinder I had in the shop. Yah! I’ll be able to test the cylinders every year now to see how quickly the exhaust guides wear.