Firewall Repairs

Today I put in some long hours and got a lot of things done.

While sanding the engine mount to prep it for painting, I found an vent hole which had never been closed off because a support rod was in the way. I just drilled a second hole, welded it closed, filled the tube full of linseed oil and closed it off.

Since I had the engine mount off, I took the opportunity to close off any unnecessary hole in the fire wall. This was a big one the original owner had cut to allow for a DB-25 plug for the ignition system.

I tired welding, but the metal is so thin I just couldnt get a stable arc, the fiberfax just vaporizes and blows holes in the weld. Hum…what to do??

I decided to install cover plates over the holes with SS rivets. It worked out much better.

this plate closes off some holes used for the ignition system high tension leads.

There was a couple of big ones just below the cable pulley. Closed off too.

I finished painting the engine mount. Hopefully I’ll install it tomorrow if the paint is hard enough.

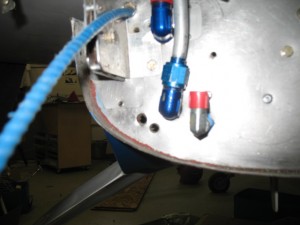

This is a one of four firewall bushing I machined out of a high temp fiberglass rod. I am using these bushing to for all wires going through the firewall to prevent any contact (shorting) of the wires. They are made long on the engine side so I can put a firestop sleeve over the exposed bushing and clamp it to the wires.