I have been busy the last few days putting things together for a change. Actually the work is getting kind of exciting! I can actually see a path to the end and feel I am over the major hump an on a more secure path knowing what the hell I am doing. Maybe it’s just a philological hump (frustration, overwhelming effort, working in unknown directions, etc), but I am kind of jacked about getting this plane done.

Whenever you are doing highly customized work, one is always faced with creative frustrations while in the exploration of new ideas and directions. Just figuring out how to design nutplates and bond them in to the plane for hidden support of the GPS and other accessories a PITA. As the customized features of pPod are slowly wrapped up, I am moving in the direction of doing things which are easier and faster to accomplish because I have already done them a few times on other planes.

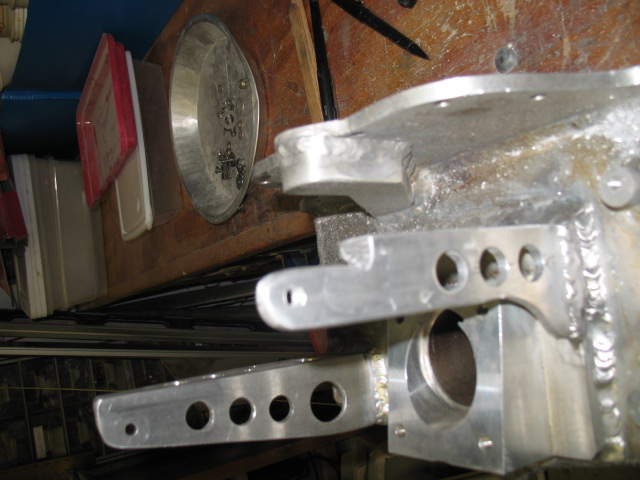

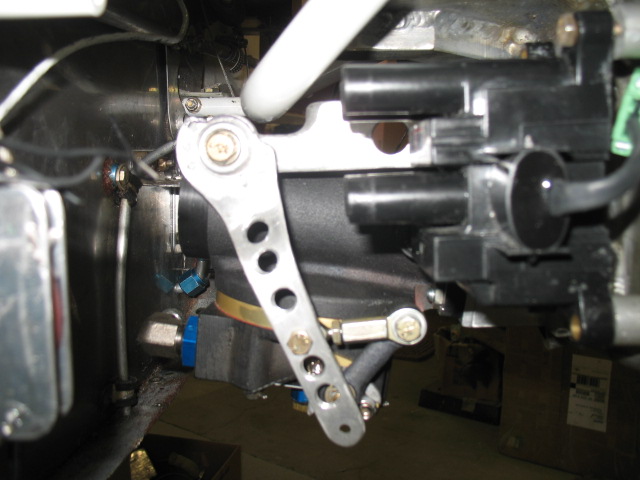

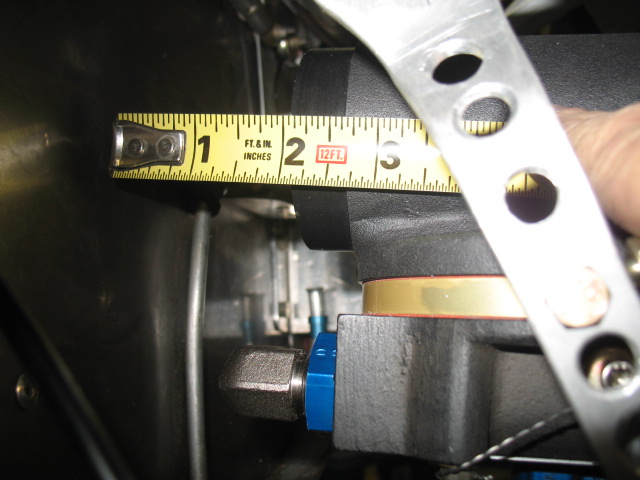

Today, I built on a controllable air door to increase cabin pressure from the NACA duct. A flapper valve seemed like the best choice and easiest to make. It has a silicon seal and a recess lever for an offset control handle. It will be bonded into the NACA inlet duct with a control handle in the front and back seat to allow a lot more air and into the cabin to increase cabin pressure when desired (such as flying through rain or in really cold weather). It works super well in my plane and wanted to transfer this feature to pPod.

Yesterday the nut plate supports for the LED side light, iPod music player, lighting dimmer control and Garmin GPS mounts were bonded into the plane.

My shipment of #14 Adel clamps arrived and which were taken apart and re-bent into a rectangular shape to support both hoses with the same clamp. It is cheaper than using two clamps and will reduce the heat impact on the click bond fastener. Besides it looks way cooler and more professional.

The oil hose routing and attachment to fuselage is done. Tomorrow a bunch of components will be glassed then all the control push/pull on the port side will be routed and mounted. The overall philosophy is to install everything into the plane prior to wiring, disassemble everything, paint the interior, then remount everything THEN you wire the plane. Lots to do, but it is starting to get exciting!

I was thinking this morning about the work on the plane this morning while on my walk/run.

Imagine buying a really nice house. You enjoy for just a week and then decide to make some changes. A contractor is found. You decide on a MASSIVE overhaul. The first thing done is to completely gut the house completely, tear out all the sheet rock, wiring, plumbing, doors, trim, bathrooms, fixtures, floors every freaking thing! Your are then back to just a shell. A structure of which looks complete from the outside, hollow and empty on the inside. The goal is to put it all back together in an high tech way with custom everything, with the latest big screen home entertainment system, computer controls, custom trim and furniture. THE MOST CUSTOME AND ADVANCED HOUSES OF ITS TYPE IN THE WORLD! As we used to say in the Navy, “I shit you not!” .

This is the challenge I have given myself. Completely disassembling a flying plane back to just an empty structure. Rebuild this shell into a LongEZ the likes of which the world has never seen. This plane will extremely fast, most likely the fastest EZ in the world. The clean cowl, custom made P1 Prototypes low drag oil sump, remote fuel sumps, and very low drag air frame means SPEED! The electronics on the plane will include the most advaced equipment avaliable I know of no other canard in the world flying with ADS-B or even ARINC-429 . As a matter of fact, most builders have never even heard of these aviation communication protocols before or if they have, dont fully understand the terms. I recently read that only 1000 planes in the world are flying with ADS-B.

I dont know the exact date this bird will fly again, but fly she will. I’ll be at the controls for the first flight of a new generation of canard’s. The world’s fastest and most advanced LongEZ ever created. I can’t wait…….