Oct

07

2010

Here is a quick update

The panel is now in Montana being lettered. The initial pictures sent me by Aerotronics showed the lettering was not put on straight. It was a bit skewed. A quick call to the company and they are redoing it again. This is certainly the panel from HELL!! It is cursed! I’ll be afraid to to touch it when I finally get it back as some of the luck of the ??? might rub off.

The engine is mostly put together. Intake, exhaust, alternator, fuel injeciton are all done. The downdraft cooling system has not been competely installed as I need to put some fuel in the plane and purge the lines prior to buttoning it up.

I have run the power lines to the alternator and starter. All the rest of the wires are temporarily mounted to test wire runs.

The final step on the engine to find a home for the oil cooler and fuel injection air intakes . I have found a good spot to build inlet plenums and should only take a few days to complete. The bad news is I have to use some SCAT tubing (yuck) on one air intake the good news is when done I can finally get to the wiring! Cant wait.

Sep

20

2010

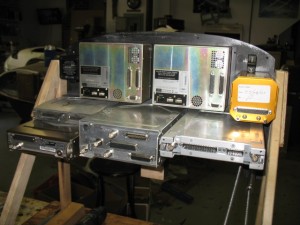

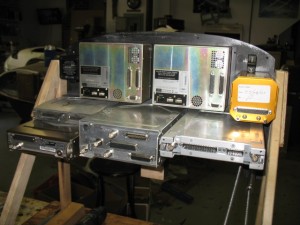

The panel had the last fitting today. Found some issues I still needed to correct but I think it is just about done! Yeah! Although the panel easily is removed from the plane with the radio cans in place with no wires, I’ll need to write a procedure up on exactly how to remove all the interferences prior to actually taking it out. There sure would be a number of steps….

It is quite impressive with everything in place. The Trio Autopilot head was sent back to Trio because the display was not working. I also wanted to get it upgraded to the latest firmware (which includes support for Grand Rapids GPSS and GPSV.

Also completed to day was the baffling mods for the engine. As soon as the instument panel is set off for lettering, I’ll be able to complete the engine work.

Sep

10

2010

The last few days have been total devoted to getting the panel ready for lettering as I thought the effort would be short and easy. While looking at the panel I decided I didn’t like the big chrome bezels of the LED lights. I floxed the holes shut and redrilled them to accommodate simple LED holders. I dont like the knobs either, so I am going to machine some that I like. It is easy to do on a lathe. I also cut the shaft of the potentiometer control shaft off so I can reduce the exposure of the knobs.

The before look

The after look.

I decided it was best to fully assemble everything to make sure there were no surprises. The nutplates for the panel were floxed in and I like the stiffness of the panel when placed in it’s frame and secured.

Note the gold box in the above picture (the autopilot elevator servo.

When looking from the other side I noticed it was going to hit the com panel and transponder radio cans. FU****K!! The servo has to go.

You can see the carbon box just forward of the servo into which the radio can is secured. Bye bye, servo….

Not only did the servo hit but when I changed out from a Garmin 327 to a Garmin 330 transponder, I found the transponder’s can was 2.5″ longer than what I had planed for which made the can hit the elevator control rod. SH*T!

Major redesign time! Hum, IF I switch the places of the com and transponder then the com panel (with the shorter can) will allow me to gain the clearance I need for the control stick. After a few hours work…done. Clearance is good now.

Since the panel is taking longer than I anticipated to finish off, I took a few hours to to get some critical measurement from the engine I needed to send to Airflow Performance so I could get the fuel lines made. AFP currently has the fuel servo for a minor change, and they were waiting for me to call them with the injector line lengths so they could build them and ship all the stuff back to me. I finished making the cylinder cooling plates (an improved design to the down draft system) and took some heavy wire to simulate the fuel lines and route everything to make template lines.

After a while of bending, cutting, rebending, etc I was satisfied with the routing and placed my order for the lines. They should be here by next Wed. I’ll then be able to fully assemble the engine!

I found a new home to re-install the autopilot servo. Here, I am using the fiberglass spring template to make a new control arm for the elevator torque tube. I’ll attach the servo to this tab. It will act as a carbon control arm for the servo.

Sep

07

2010

Today was dedicated to getting the panel finished so I can send it out for lettering. It has the longest lead time to get back to me. The radio cans were positioned and the nuts were bonded to the side boxes to hold everything in alignment after disassemble.

Next was milling the backside of the .200″ thick carbon panel down to .125″ thick in for some of the switches. Some areas were milled to .060″ for LED lights.

Two “Data Ports” were machined into the panel. These ports will allow the pilot to upload flight plans, software, maps, etc to the Grand Rapids Flight system, as well as down load recorded flight data (air and engine) to be analyzed after landing.

The switch at the bottom of the panel is actual an air valve which will allow the pilot to have an “alternate static” port in case the fuselage port gets plugged. I think I may look for some different knobs. I don’t like the size of these all that much. I think they are a somewhat big.

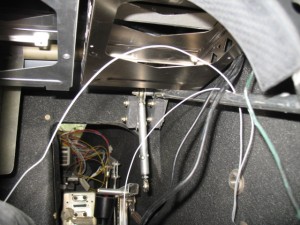

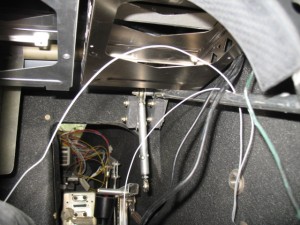

I started laying out the wiring for the GTR system. All these wires are in addition to the ones in the back of the plane which are for the engine monitor. This doesn’t come close to what needs to go into the plane. When I was a kid I used to think it was fun to unravel a mess of tangled string. This wiring rats nest makes me think of those days long ago…..

Sep

03

2010

Finished installing the cans for the radios today and wanted to see how the panel looked together (for the most part). Found a minor lettering issue I’ll need to resolve before it is sent off. This is certainly the most advanced LongEZ panel in the world. I have never seen an EZ or Berkut with this much electronics. It is going to be a blast to learn to fly this bird with all the computers on board….

Wow, I sure have a lot of conectors to hook up to wire the panel….. should be fun!

Sep

02

2010

I finished up the work on the WVO car controller. I built a test stand to simulate all the connections and switches of the car and dang it, the thing worked as I originally designed it. I dont know why I thought it was a bad design. After a few hours work on the timer circuit it now works perfectly.

Basically, in AUTO, the WVO system now waits for the coolant water to get up to 60C, turns on the oil supply valves, turns on an electric oil heater to keep the oil a minimum of 50C (it cycles as necessary).

If the fuel in the supply tank gets to 1 gal, it shuts everything down.

When the car is turned off in AUTO the system closes the oil valves and keeps the engine running for 30 sec to purge out the WVO before it turns the car off. Very cool… The next step is to install LED’s and the switch in the dash with some nice lettering to make it look good. It is amazing to me that a commercial unit which does the same thing this does cost $350. Mine cost about $25.

The engine is now on the plane. It really looks good now with the newly painted engine mount and engine.

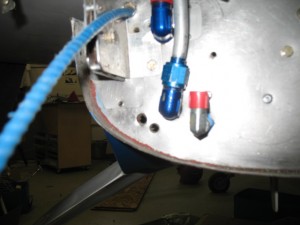

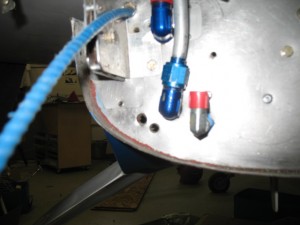

The is a close up of the firewall penetrations. After all the wires are run, I will clamp the firestop tubing around the wires.

The insturment panel came back to me unletter but with some nice glass work done around the leg openings and radios. I spent all day fitting the radios to the panel so they would have exactly 1/4″ exposure from the panel.

Tommorow, I’ll finish screwing the radio boxes to the panel and some other detail work which needs to be done prior to sending it off to be lettered.

Aug

30

2010

Yesterday, I stared making a new batch of fuel probes which have been selling surprising well. Thats when I found Mr. Lathe was very sick….. Yikes, he is one of my best friends in the shop!

Stop the presses, this is an emergency!!

After downloading the wiring diagrams from the web, I spent hours trying to figure out how those dam low paid chinese gals wired him up. At least the numbers were in english. Imagine, hand drawings of the wiring! Chicago Tools (Harbor Freight stuff)=Made in China junk (but the price is soooooo cheap).

After a few hours trouble shooting, I found a contractor had gone bad which has been ordered 2 day express from Calif. I should be back up and going on Friday! Woohoo!

Replacing the contractor out (upper right box) from this wiring mess is going to be a challenge. I think I would rather take part the dash of the car again.

After the trouble shoot bout with Mr. Lathe, I started back reassembling the engine. It looks really good now.

Before I remount it on the engine, there was some firewall work to be done such as pulling wires through my bulkhead fittings. What a mess! At the top is a 95 db backup beeper. It is great for scaring birds on landing and warning people at airshows to keep out of my freaking way!

This is a piece of 1/8″ copper tubing which will be for the manifold pressures sensor. I prefer putting a copper tube though the bulkhead instead of just running a piece of rubber tubing. I think it is safer and is less trouble some when removing the engine.

I also stared working on the wiring of the engine information system area. It is starting to get fun now. I love wiring!

Aug

23

2010

Yesterday started off with a quick 10 minute trip to a “Flyin Breakfast” at Monks Corner. I helped a little with the food and setup, but mainly I just enjoyed a great early morning flight which was very nice.

I wanted to show you the progress on the the construction of Boeing 787 Dreamliner plant. They are still adding to it. The size is just immense! I have to pass it to go to my hanger, so I see the progress on a regular basis.

Only about 40 people showed up at the breakfast. Not many planes either as I think the weather (low clouds) may have put some attendees off.

I took the opportunity yesterday to finish off the oil tank part for my grease car. I spent hours welding aluminum and finally thing I am starting to “get it” on welding this metal. It certainly takes a lot of practice. At least the welds are not coming like big blobs or melting through. It takes a huge amount of current (175 A) and the TIG handle would get so hot I would have to let everything cool down ever 15 minutes. The inside of the tank is built with a baffle and a coil of 5/8″ Al tubing which I can circulate hot water through for additional heating of the cooking oil if I ever decide to use it (cold weather ops). I always like to plan ahead.

I have been using a 5 gal gas can for the last few months which conveniently fit into a well on the car for the cooking oil. It held 5 gal of oil and gave me a range of about 110 miles.

The new tank holds 8 gals of oil and it also has a low level alarm which activates at 1 gal. It looks a lot better than my red tank.

Speaking of red…. I wanted to paint the engine one color since the case was red and the accessory case was gray. It took a lot of time to paint but the engine is again one color. Tomorrow I’ll replace all the bolts with new ones .

The new look. Kind of like it..

Aug

20

2010

The oil pan is back from the machine shop. They only charged $80 for machining the flange flat. I hate oil leaks and I am sure it was worth the effort and money.

I have a long list of things to do from painting the engine accessory case to mounting ground blocks before I can put the engine back on the firewall. It was really to my advantage to take the engine off the plane (took less than 1 hr) to gain access to the firewall and the front of the engine.

This shows the firewall through bushings I made and installed. Since they are high temp fiberglass products, they are floxed into the firewall. They are nicely rounded on each end to prevent chafing of the wires and possible contact with the grounded firewall. The starter cable has over 600 amps flowing through it and I want to make sure there is no possible way to contact the firewall, ground out, and start a fire.

The bushings are 1″ long with a 1/2″ flange exposure into the engine compartment so I can put firestop on the end. In the unlikely event of an engine fire, the firestop will prevent fire/smoke from entering the cabin from the wire openings.

Aug

18

2010

Today I put in some long hours and got a lot of things done.

While sanding the engine mount to prep it for painting, I found an vent hole which had never been closed off because a support rod was in the way. I just drilled a second hole, welded it closed, filled the tube full of linseed oil and closed it off.

Since I had the engine mount off, I took the opportunity to close off any unnecessary hole in the fire wall. This was a big one the original owner had cut to allow for a DB-25 plug for the ignition system.

I tired welding, but the metal is so thin I just couldnt get a stable arc, the fiberfax just vaporizes and blows holes in the weld. Hum…what to do??

I decided to install cover plates over the holes with SS rivets. It worked out much better.

this plate closes off some holes used for the ignition system high tension leads.

There was a couple of big ones just below the cable pulley. Closed off too.

I finished painting the engine mount. Hopefully I’ll install it tomorrow if the paint is hard enough.

This is a one of four firewall bushing I machined out of a high temp fiberglass rod. I am using these bushing to for all wires going through the firewall to prevent any contact (shorting) of the wires. They are made long on the engine side so I can put a firestop sleeve over the exposed bushing and clamp it to the wires.