After a few months of hard work on the plane, I am going to try and get back into my blogging. A number of people have berated me about updating my site, but to my defense I have been busy and also got a new new computer (an Apple) which has been kicking my ass. Being an original computer user (before the days of Microsoft and Windows), and a Windows user all my life, the Apple operating system is a bit of a handful for me… Anyway, I am going to try and fill in the gaps, but for right now, I’ll just cover some of the cool things I have done very briefly.

I now have over 30 hrs flying the bird. She is a true joy to fly. BLAZING FREAKING FAST, (top secret at this time), right now I think she is one of the fastest ever built, handles like a dream, terrific avionics (which I can’t figure out how to use) about like my Apple computer but still, this is a plane I really love to keep forever.

As I am finishing up this project, there were a few last minute things I wanted to do prior to flying it to L.A., Calf for painting and upholstery.

James Redmond who likes to race his Berkut pioneered the use of winglet root fairings and sweep back rudder tips in an effort to increase speed. The speed improvement of the rudder tips (while they looked cool), were hard to measure. James claims the root fairing gave him a few extra knots, so I had to have them.

Not to be out done, if a little sweep back on the rudder tips is good, more is better! I wanted a bit more of an aggressive look.

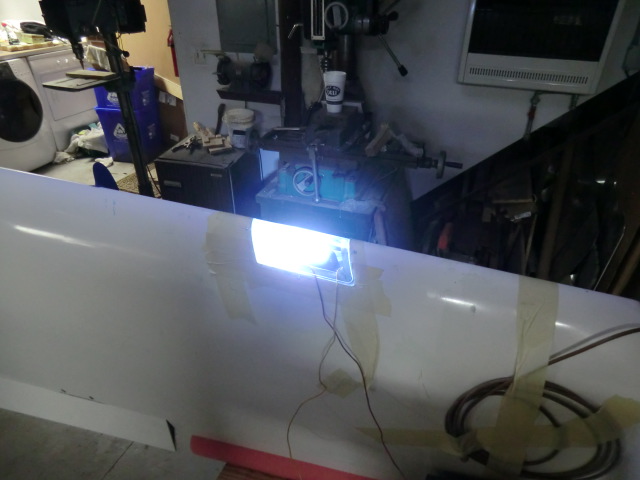

This is a picture of Jim’s winglet root fairing.

I also did the winglet root fairing too.

Overall, modification of the wings was a very easy process. It only took 2 days to accomplish on each wing with one extra day for filling and finishing.

As soon as I figure out how do do web pages, I plan to build a page for each part of the process for others to follow.

Next up is the canard mods..