Finishing the Oil Sump

Today’s efforts were totally concentrated on finishing the install of the hardware for the fuel injection system so I can send the fuel servo back to Air Flow on Monday with the order for tubing.

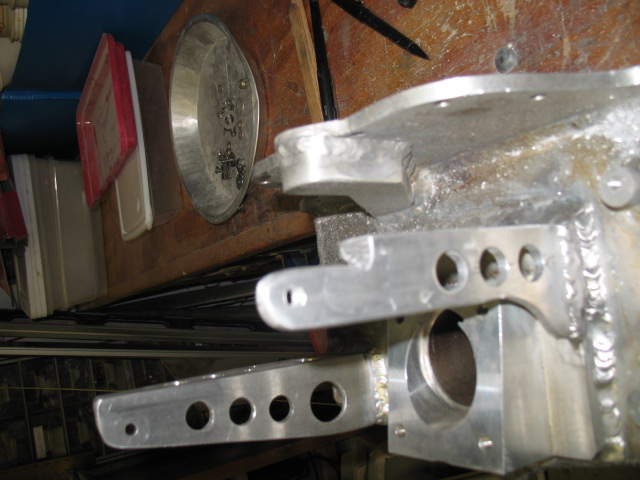

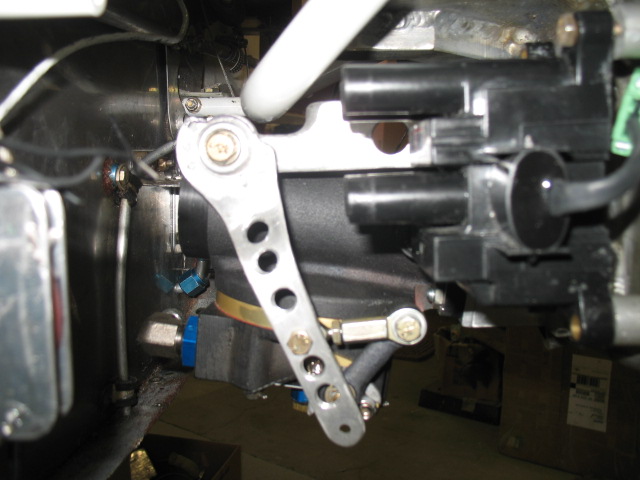

I needed to mount the purge valve, the fuel totalizer (Flow Scan) and the distribution spider. Getting the push pull cable for the purge valve was a challenge because I had to go through 3 iterations of the mounting bracket to clear everything. I also had to weld on a support for the fuel spider on the cowl. I am getting better at Al welding, and now I wish I had modified the cowl myself . A lot of money was spent at the machine shop and I have the feeling they might have overcharged me. I feel bad about it now…. bummer.

The fuel distribution block support was welded on the back of the sump and is insulated with a phenloic separator.

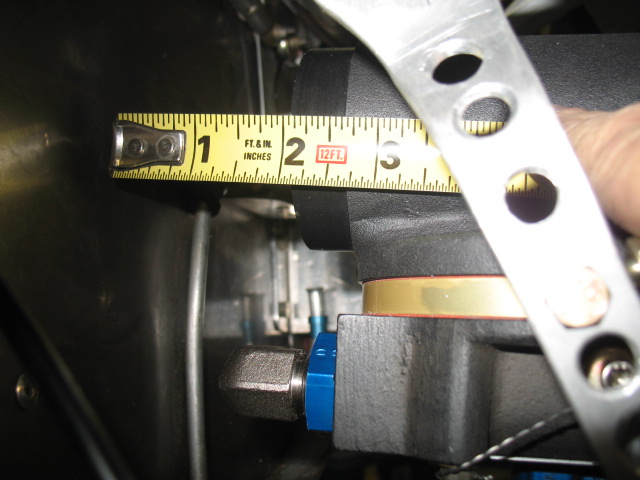

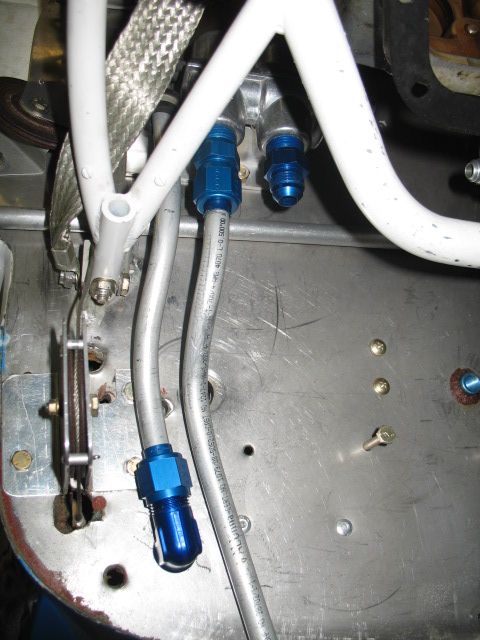

Here some views of the sump. I found out I can use 1/4″ SS fuel lines between the components since they are all fixed to the same mount. It make for a nice clean install.

I was concerned about the hot sump affecting the Pmag coil which is mounted on it. So I took some scrap phenolic material and manufactured some washers for extra insulation.

Pmag mounted on the sump. I am beat…done for the day!