Apr

16

2011

Today I worked on “Earth Buckets”. I got the idea from my buddy Jerry who is growing lots of veggies in “Earth boxes“. It is a very cool product which mirrors natural hydrology principles to create a self watering growing eco-system.

I have terrible soil and sparse rain so I wanted to do some experimentation with grown veggies in such a system. Didnt want to pay the money to buy a bunch of Earth Boxes, so I came up with my own solution from a landfill waste stream. Earth Buckets.

The principal is: Water is stored in the bottom section, you fill the water reserve via a tube, water is wicked up to the main growing area via capillary action and you put GOOD grown soil in the top secton of the bucket. Easy.

I have been collection old 5 gal buckets on the side of the road to use as supports for the soil. I also purchased a bunch of buckets from Lowe’s because I wanted my garden to look consistent.

Drill a large hole in the bottom of the old bucket, then saw off most of the bucket to make the shelf and using some scrap PVC to make the tube for the wick and filler.

The assemble bucket. Simple. Be sure to drill a hole in the side of the bucket just below the soil shelf to allow excess water to drain out.

A bunch of the read for dirt and planting!

Apr

15

2011

The wiring is essential complete, but now begins the process of carefully checking out each system prior to energizing to ensure I dont hopefully fry and expensive piece of equipment when I power it up. During the last few days I have been hard at work trying work out the electrical issues.

Overall the hardest problem to get rid of was electrical noise in the entertainment system. I hate noise in the headset and will go to great lengths to get rid of it. Noise problems are especially prevalent in composite planes and have spent over two days figuring out what was causing it and solving the problem.

I found the stereo input to the com panel is super sensitive to almost any kind of noise. I had to make TINY Delron bushing on almost all the connectors (even electrically isolated jacks) to prevent noise. This a a picture of a a fairly large one bushing I made as a “storage” jack for the stbd side 1/8″ stereo jack. I also had to replace and move some of the wires to eliminate the problem.

I even found out when the input jack is disconnected from the GPS, just touching it or having it bump into something will cause a buzz in the headset. To prevent this I made a bushing to park the jack into.

The jack was installed in the the stbd ball mount.

When the input plug is not being used, the I can insert it into the bushing which prevents any noise.

After taking the electronic equipment in and out the plane a number of time, I found I could completely remove all the electronics from the dash to have complete access to all of the wiring behind the equipment in about 10 minutes.

The EFIS panels (since they are custom machined and back set in the panel) have to removed from the front. They are disconnected, turned sideways and come right out.

I love the ability to quickly and easily remove them to make changes to the wiring.

After spend many frustrating hours trying to get the ADS-B properly configured and all the computer systems to talk to each other, I am finally happy with the wiring, and now it is time to tidy up the wiring with tie wraps, button everything up and start installing the interior.

Apr

14

2011

Last night while working on the plane, I knocked out my front tooth. Shit…. I had a temporary crown on it and luckily I didnt swallow it!

A quick trip to my local dentist to have him re-bond it to my tooth and I was back at work! Hopefully the temporary will stay on until I get the plane to California and get the permanent crown intalled by Pat.

I have also decided that if the tooth comes out again, I will NOT have it re-bonded in and just go around with a hole in my smile, looking like a local southern boy. I want to see how people react to me as it should be fun and quite entertaining! Besides, not having my tooth in will motivate me to work harder and get the plane done. Certainly wont be able to get a date looking like this….

Apr

12

2011

Today Charleston, SC celebrated the 150 anniversary of the beginning of the American Civil War.

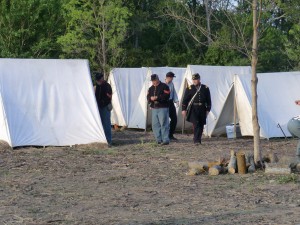

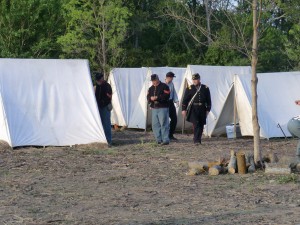

At Patriots Point in Mt Pleasant a group of civil war reenactors camped out in a baron field and were having a great time.

Our South Carolina war fighters!

What fun…. sitting on stools hanging out and chatting. Kind of reminds me of what I do at Oshkosh (except we have lots of beer and roasted corn!)

What I really wanted to see was the firing of the civil war mortars. Later in the evening, the reenactors started firing all the guns (about 10 of them) in different combinations such as rapid fire, continuios fire, free firing, etc. It was loud and fun!

You can not see it very well, but Fort Sumpter is across the water and is what the solders would have shelled.

Apr

11

2011

Bubba has moved on. Earlier this week, Tony and I flew up to NC to check a cozy out for a prospective buyer (smart move). After checking the rotary powered cozy out, FOUR builders emphatically told the buyer it was a piece of crap. Fuel leaks, structural issues… a plane worthy of a chainsaw. The buyer was faced with 5 days on the east coast with nothing to do until his flight back home, so I offered him a place to stay at my house so he could check out Charleston and more in the south east. Make a vacation out of the trip.

Somewhere along the way, we started discussing Bubba and he wanted to check it out. A quick trip to the airport and an hour later I agreed to sell him.

Two weeks late Soheb showed up with a truck and trail to move Bubba to his home in Vancouver BC.

The engine was taken off to allow for easier handling of the fuselage.

Bubba was tilted up at an angle on the trailer to ensure it did not exceed the federal width restriction on a trailer load.

Lots of blocking and hold down straps.

Sort of looks like a modern sculpture on wheels!

Bye Buy Bubba. I would have loved to have flown you again but I have my ultimate airplane to build and it is time for you to go to your new home.

Apr

08

2011

Gerhardt wanted to filter some more WVO for our cars…. The problem is the waste oil is cold and my propane powered heater just didnt seem to work well. The best I could get out of was 0.5 g/m.

I decided to try an electric heater instead. Since the oil is non-conductive there is no risk of shock.

A quick trip to Lowe’s resulted in a $15, 1500 watt 120v hot water heater. An old extension cord was sacrificed and in 20 minutes I built a electric tank heater.

This showes the starting temp of the tank.

In 24 hours we went from 65 f to 137 f. I was able to pump 4.5 h/m through the filter with ease! What a great system. I was able to filter 300 gal in about an hour or so. A quick calculation showed that at the current utility rate, heating up the tank cost about $4 which means the it only cost me about 1.3 cents per gal of oil to run my car.

All that time I wasted with making the copper propane heater…..oya what a waste. Maybe I can use it to make some moon shine.

Apr

06

2011

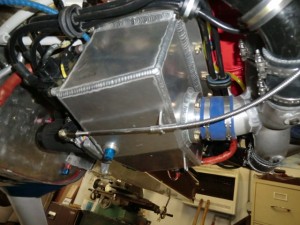

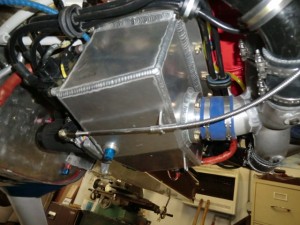

While checking out the individual power circuits, I found a MAJOR mess up. When I originally designed the oil pan I had the fuel servo hanging up side down. Later I flipped it right side up due to space considerations. I didnt take into account the push-pull movement and I found out my throttle cable now moves in the wrong direction. Shit….

After thinking about it for a while I came out with a fix which works very well. I installed a SS shaft with a support bearing for the cable to attach to. This effectively reverses the movement of the throttle cable and now everything work correctly.

Today was also noteable as I finally powered up the EFIS panels.

It has been quite a chore in checking out the wiring and powering everything up. Just about every circuit has had some issue from missing grounds to connector broken wires issues which needed correction. Slowly everything is being checked out and put in service. Tomorrow it will be correcting an minor issue with the EFIS panels and starting on the radios which are the last to do. I want to have all systems up and operational by Friday or Saturday!