Tire Valve problem Fixed

Over the years I have had a few flat tires due to the tube splitting or being cut near the filler valve on the inside of the tire. The latest time just occurred is when I flew down to FL on my way to my 2015 Bahamas trip. Fortunately I had a spare tube on board and with the help of Ed, was able to replace it in his hangar.

Additionally, most times when inflated it always seemed like the fill connection was jammed up (rotated) against the side of the rim thus making it difficult to put air into the tire.

In looking into the problem it is easy to see why it occurs.

There is a 5/8” hole in the rim and the rubber on the fill tube is less than 1/2”. This causes stress in on the neck of the filler tube when pressurized since it is trying to push its way out into the larger hole and at times cuts the tubes in this location. The difference in size also pushes on the fill tube into the larger hole causing it to rotate a slight amount toward the rim on the outside making it harder to add air to. The cutting of the tube has happened 3 times over the years and to many others I have talked to.

The cure is making a simple small bushing which prevents the tube from being pushed up into the rim and provides additional support to the soft rubber of the tube. You might just be able to use a large diameter washer to support the tube and keep it from pushing in to the larger hole.

Here is what they look like.

How the insert looks on the rim. I am sure with air pressure it presses itself flat to the contour radius of the rim.

For assembly, I first push the bushing the tube prior to inserting the tub into the tire.

With the bushing on the tube, it prevents the tube from being pushed down into the hole on the rim

This supports the filler tube, and keeps it from rotating keeping it straight thus making it MUCH easier for adding air.

No more cut tubes, easier filling. A simple fix.

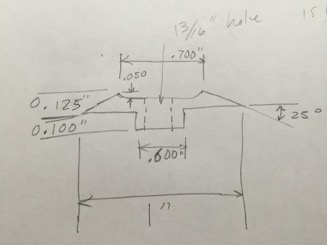

This is the general drawing I used for making the nylon bushing. It is the only 1” material I had, although if the pressure distorts the bushing, I’ll make the next set of of some scrap Al I have.

The numbers are approximates so feel free to play.