Canopy Sealing V-Seal

I have found the V-seal to be incredibly effective. The main problem with most seal systems is over crushing of the seal and using Home depot house weather stripping to seal the canopy. It means your are ALWAYS fighting the seals to close and lock the canopy, over crushing of the seal, and the mis-matching of the canopy to fuselage causing air leaks where the canopy to longeron distance is too great. Imagine a car door. The door gaps are engineered for the seals. The seals are NOT just haphazardly chosen to fit on to hand made doors after they are made.

In order properly seal the canopy and make the canopy easy to close, you need to engineer the canopy for the seal. This requires a bit more effort than just throwing in a seal and hope it works. I have zero air and water leaks and the canopy is super easy to close and lock. So can you.

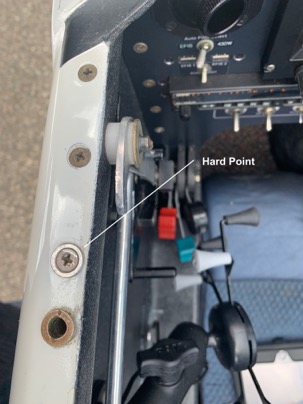

You do this by making a hard points which only allows a canopy to close down to a fixed point, “molding the canopy” to the longerons and THEN using the appropriate seals (V-seals).

Making a proper canopy seal.

1. remove all the existing seal.

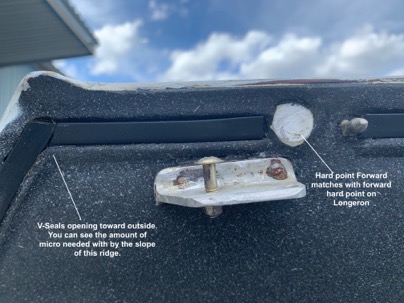

2. stack washers on the front and aft end of the longeron where the canopy would hit the longerons making sure the outside of the canopy aligns with the fuselage. This limits the crush of the seals, aligns the front and back of the canopy to the fuselage, and ensures easy latching of the canopy hardware.

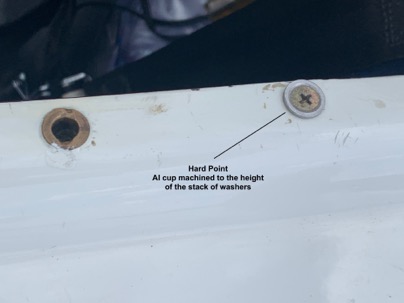

3. Drill the the place where the washers are stacked and make a permanent standoff of the same height (measure the height of the washer stack) for canopy closure. I just made a Al cup and used a AN3 screw. You can put a bolt with washers under it…whatever it takes to make a hard point for the canopy to close down to.

Aft hard points:

4. Adjust your canopy closer hardware to this new canopy closed position.

The V-Seals (Any seals) require about 30% crush to prevent deformation. Since V-seals are about .250” high, this means about .190” opening (trough) for the seals to rest in. Since your canopy (like most) has an inconsistent gap distance you need to correct that. Since you have previously established a fixed hard point for the canopy to close to (the hard points), you can now mold a surface for the seals to rest in.

5. Cut some Luan plywood (its about .195’ thick) the width of your seal (about .25” wide), box tape the longerons, heat glue the luan strip on the tape and cover with another layer of box tape. Wax. Tape off your canopy tape off the area you dont wish micro to get on to. Slather some micro on the canopy, close and lock the canopy (to the hard points). After cure, open the canopy (this could be challenging, so mold short sections at a time). Clean off the over microed areas on the canopy you previously taped off.

NOW you have a molded trough to put your seal in that has a consistently .195” depth, and hard points which ensure the fuselage to canopy is properly aligned, and the latching mechanism is easy to use.

Glue your V-seal in place. The best way I found is to wipe the back side with MEK or some cleaner, and glue in place with Pliobond adhesive. The seals will never over crush, they will open up with differential air pressure to prevent leakage and the canopy will be very easy to close and lock.

Overall, it is a weekend project. My canopy to longeron is within .010’ around the entire perimeter (Yes I checked), and I have never had to adjust the hardware or had air leakage. Additionally, I never had to readjust the canopy closure latches. They are always smooth and easy to latch.