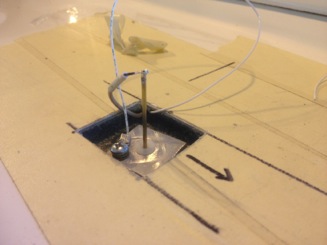

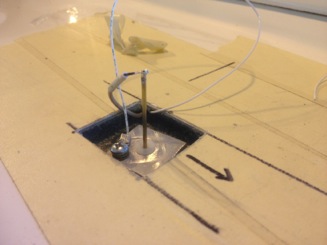

Today wrapped up the installation of the fuel probes. I have been taking my time and documenting every step along the way to be able to apply this installation experience to improving and updating the installation instructions.

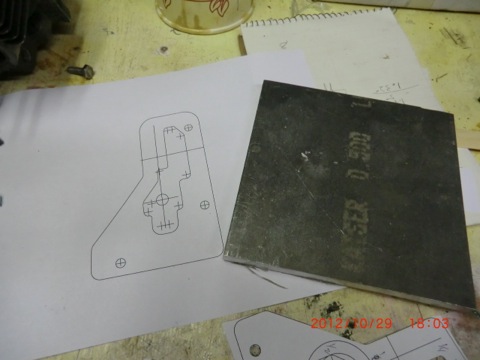

I have already found a few issues that I need to address such as probe length and size of the base plate.

I have also discovered some new techniques for easing the installation process. Simple tools to make. I wish I had more opportunities to install the probes (more than just Pat’s and mine) as it would only get easier to do with practice.

I have also discovered some new techniques for easing the installation process. Simple tools to make. I wish I had more opportunities to install the probes (more than just Pat’s and mine) as it would only get easier to do with practice.

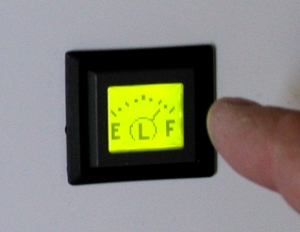

When finally installed I wanted to leave the square installation hole cut in the strakes to be highly visible. I’ll paint epoxy line black and

label the cover “Probes” just as a conversation piece. It would be easy to fill and finish the open and no one would every know the work was done, but why hide what I want to share with others. Electronic fuel probes… If you can’t be smart, be audacious! Free advertising!

Can’t wait install the electronics (maybe next week) and calibrate the electronics.

FEDEX delivered my pool liner today. Hopefully, next week will be the last I’ll be on the plane issue and can start back on my pool and deck. Its a great time of the year to be working outside and I want to take advantage of the mild weather.

USP delivered my Trio Pro Autopilot head and vertical servo today. I was having issues with the vertical servo which wasn’t isn’t too surprising since it was installed in maybe 2002? when I started as a Beta tester for Trio. Mine was one of the earliest (second maybe) EZ’s to have a Trio Altitude hold system installation. It was still in development, which gave me an opportunity to make improvement suggestions and find bugs. Trio really impressed me by listening to suggestions for features improvements and was from the beginning was extremely customer focused. I know because I have dealt with them since the beginning.

I remember seeing my first Trio product at Sun and Fun in ?????? year. They just developed a replacement for the NAVAID wing leveler which I purchased as it had more bells and whistles then the old system I had. Over time I developed a relationship with Chuck, Sid and Jerry (the tress amigos, the Musketeers, , the TRIO of Trio Avionics). I kept bugging the boys to develop an Altitude Hold system and when it became a reality, I was honored to be chosen as a Beta tester. Enough of traveling down memory lane.

During my Western Tour trip the vertical servo started acting flakey. Sometimes it had a hard time engaging, but always could be coxed into working (about like me). Fortunately, I didn’t have any major issues with it as it would have been absolutely, cave man primitive to have to hand fly the plane for the 44 hrs trip.

Chuck found for some reason the spring was longer than design and some rollers were sticking. Probably due to being a prototype as it was one of the first lot made. It was fixed, the software in the brain up upgraded, and I had it back in a 1.5 weeks shipped ground to California and ground back. I think it was only in the shop one day. What a great company.

Speaking of a good company, I never really considered using the USPS (post office for you unenlightened) to ship all my crap. I sent the hydraulic lifters to Oklahoma on Wed and it arrive today! Talk about amazing transportation service.

The box from Trio shipped UPS on Monday from San Diego, via ground and it arrived today (5 working days). I use a Click and Ship flat rate box (the small one) which only costs $5.15 and it shipped to Tulsa in 2 days. Freaken Amazing!

I have been using flat rate to send anything I could which is small, but this is the first time I clicked the “Track Shipment” button. This service is free. Today a delivery email showed up with the following tracking information.

Delivered TULSA OK 74115 10/19/12 10:19am

Arrival at Post Office Facility TULSA OK 74115 10/19/12 6:34am

Processed through USPS Facility TULSA OK 74141 10/19/12 2:03am

Depart USPS Sort CHARLESTON SC 29423 10/17/12

Processed at USPS Origin Sort Facility CHARLESTON SC 29423 10/17/12 5:51pm

Dispatched to Sort Facility NORTH CHARLESTON SC 29405 10/17/12 5:15pm

Acceptance NORTH CHARLESTON SC 29405 10/17/12 12:14pm

If you follow the time line (bottom up), you see I generated the label at 12:41 on Wednesday, made it to the post office and departed Charleston sort at 5:51 that evening. The box arrived in Tulsa sort at 2:03 AM on Friday morning and was delivered at 10:19 am that morning.

HOW IN THE HELL DID USPS THEY GET IT THERE SO FAST?

I would be freaking amazed if it was ground because just the drive there would be 12 or 18 hrs? The package must have gone by air. So for $5.15 you can ship something (ANY weight, if it fits it ships) by air across the country? No way! If so Wow what a deal. Now that know this little trick, I’ll always click “Tracking” to see how fast it is delivered. Should be interesting.

BTW, Shipping via USPS is so easy to do. You order boxes on line and have them delivered to your house for free. You create, pay for and print the shipping labels from your home computer, and walk out to your mail box in your bare feet with a mug of coffee in your hand. and shazam , it is picked up that day and jetted across the country for a third of the cost of messing with UPS or FEDEX. I don’t even have to start car!

I am still conditioned to uses FEDEX for high value stuff and for detailed, butt kicking tracking, but I may have to looking into using USPS more of the time.

USPS. Amazing service!

I have also discovered some new techniques for easing the installation process. Simple tools to make. I wish I had more opportunities to install the probes (more than just Pat’s and mine) as it would only get easier to do with practice.

I have also discovered some new techniques for easing the installation process. Simple tools to make. I wish I had more opportunities to install the probes (more than just Pat’s and mine) as it would only get easier to do with practice.