Amazon is AMAZING

Lately, I’ve been doing a lot of Shopping with Amazon. I am beginning to find that Amazon has almost everything that I need to order. From computer stuff, kitchen equipment, personal hygiene, automotive parts, just about anything imaginable!

Many times, the prices are as good as EBay, or anywhere else on the web, I get 2 day shipping AND returns are a snap. In some cases, you might a dollar or two buying somewhere else, but the convenience of ordering on line is worth it. Besides, they really take care of the customers. I pre-ordered a Blue Ray DVD and after was shipped Best Buy was selling it for $4 less. Crap, it would cost me more to send it back so just decided to not bother. The next day to my surprise and pleasure Amazon automatically refunded me $4 because they found a lower price and price matched it. As a PRIME member, I automatically get two-day shipping which is well worth the extra $79/year and you also get to stream movies and TV shows.

On Monday morning, while taking about 300 book to Goodwill, I broke the tail gate handle on the truck. Crap plastic cheap ass stuff. Hell, the dam thing only lasted through 13 years of abuse! I thought about welding one up and make my own, but in a moment of sanity, I decided to check on line before I got out the cutting tools and drill bits.

I went on EBay to order on, had actually clicked to buy one and decided to check Amazon before paying. Dam if they didn’t have it for the same low $21 price as Ebay. I can order it and it will arrive in two days ((Prime). I didn’t even want to drive to the Toyota dealer to check their price. Not worth the time or gas.

I was surprised when the next afternoon the replacement handle arrived!!

I remember reading some articles about Amazon. They are working toward having next day deliver on more items and Amazon and Walmart are investigating the possibility of same day delivery. Order by 10 am, get delivered in the afternoon ($10 extra charge). Talk about the ultimate convince. I wonder if I can do all my grocery shopping with them. Now THAT would be worth $10 to me.

The local “Newsless Courier” had an article a few months back that Amazon was able to get a special tax break from the state of SC to build wear-house/distribution center in the state. After some tense on/off moments when I thought Amazon might back out (state was giving them the run around), they finally negotiated a sweet deal for locating in SC and hiring workers. No taxes for 5 years. There are now two wear houses located in Spartanburg (3 hrs away, where Airflow is located) and in W. Columbia SC (about 2 hrs away).

I now I get everything in 2 days max, and more orders are starting to show up the next day if you order early in the morning. Yah!

The handle fit just like the original, and easily installed in the tail gate.

Now repaired and back in business!

I also fixed the handle on my drill press. I tried to repair and flox it in place once before, but did a crappy job of gluing it and it broke again.

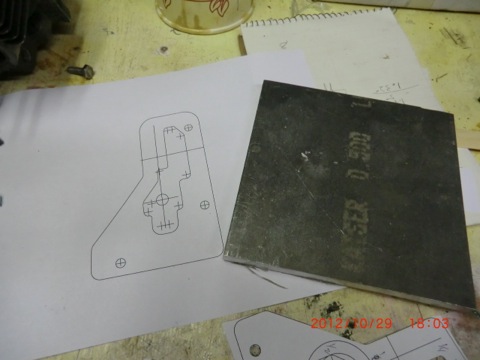

I was fix’n to throw out some AL when I ran across the metal on the right. It is what was left of the nose fork on my plane that I was just about to recycle. I thought, why not save it and have a memento.

This is the remains of the nose fork which broke off when I was landing at Greenville Downtown airport on 26 March 2001.

No wheel, no go!

I clearly remember the event (how could one ever forget). I was just touching down heard a pop, and saw something from the corner of my eye fly by the starboard wing and though, “SHIT, was that my wheel?” I looked through the little view window for checking gear position, and saw the front wheel was gone. I informed the the tower and gently touched the nose down.

The grinding sound was really loud and I sure I stopped in a hurry. Dam! I picked up the nose and walked the plane over to the parking area. After the everything settled down, we look all over the runway and grass area for my front wheel, but never could find it. The really sucky part of all this was I had to rent a car to drive up to Norfolk VA for a navy ball that I was attending. The plane was left at the parking area until I could get a replacement fork.

When I returned a few weeks later to repair the bird, the FAA had also stopped by as they are required to do after every accident, and there was a big yellow tag on the prop indicating it was cracked and I needed to contact the manufacture get it rectified before I could fly again!! I laughed a bit, called them up, told them I made the prop and it was fit to fly. The FAA… don’t like them all that much.

About 6 months later I landed at Greenville on other trip, and the desk handed me what was left of my tire. Apparently it had bounced a long way from the runway and the grass mower had chopped it up a bit.

Back to the drill press repair. Some cutting, drilling and grinding……

And now I have a new handle for the drill press an another story to tell.

This is how it was in the beginning as I was rolling in the steel sides. I a bunch of parts from old 30 foot round above ground pool someone gave me and recycled it into my pool.

This is how it was in the beginning as I was rolling in the steel sides. I a bunch of parts from old 30 foot round above ground pool someone gave me and recycled it into my pool.