Wire Lacing

I think the epitomeof a good wiring job is how the wires are bundled together. When ever I look at someones wiring, I look at how the wires are grouped together, are they in nice straight lines, do the corners have radius’s, etc. Good wiring is an art as well as science.

The most important aspect of wiring is how the wires are grouped or bundled. Lets say you have a 100 wires, it is not a good idea to bundle them all together. The problem is that when trouble shooting you can’t determine which wires goes to which plug or if you need to test a wire or spice into one, which one is it? If you have 30 white wires in a big bundle you’re got a problem.

In production shops identification information is actually printed on each wire. I dont have the luxury of having a dedicated piece of equipment to do this.

A better way is to bundle wires is to separate them into smaller groups for a dedicated purpose. An autopilot bundle, a trim controller bundle, etc. This way if there 8 wires in the bundle, you can figure out the purpose of the bundle is and therefore what each wire represents.

There are a number of ways to fasten the wire bundle together. The easiest and quickest way is to use zip ties. I dont like them but they have their place. They are heavy and the little cut ends (if you are not careful to trim the properly) will slice your hands when reaching around them. Boeing decided to stop using them in the 747’s which saved them over 400 lbs per plane. Granted, I am not using tens of thousands of them in this plane but you get the point. Besides I think they look unprofessional, they can squeeze the wire to tightly, or not tightly enough.

The “old fashioned” and I think the best way of bundling wires is using lacing cord. It is bee’s wax coated polyester cord and is the standard for the aerospace industry. I think it looks great, is very light weight and wont cut you. The only issue with lacing cord is that it is a bit time consuming to use (although I am getting faster with practice). When done properly it is very artistic.

When I went to the National Air and Space museum in Washington DC, I marveled at the wiring on the old NASA space craft. All the wire bundles were beautifully stitched together. Nice even knots and they used techniques I couldn’t even find on the web. Wire lacing is truly an art if done correctly.

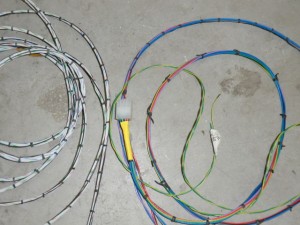

Here is a picture a wire bundle using individual knots.

Fairly easy to do, but as I was sitting (butt getting sorer by the moment) I remember seeing on the web techniques for “continues” lacing, so I did a little more research and printed out some instruction sheets. Continuous lacing uses a starter and end knots and a repeating lace stitch between them as you just move down the wire bundle. I think it looks fantastic and is much quicker than individuals knots. Not as nice as NASA, but I am getting better and faster.

Here you can see the left bundle with a continuous lace stitch and the right bundle with individual knots. The continuous lacing looks much better for sure…

I plan to lace as many bundles of wires I can. Sure makes for a good looking an professional job!